Mediterranean Sea Injection Moulds

Mediterranean Sea Injection Moulds

Manufactured from high-quality AISI 304 stainless steel. Since all components are fully compatible, you can choose the configuration that best suits your needs and expand it in the future.

- Designed for high durability (6 mm thickness of the upper and lower plate). All our Mar Mediterraneo series molds are fully compatible with each other, so if you already have the upper and lower plate, you can use another intermediate fastener, without having to purchase the complete set again.

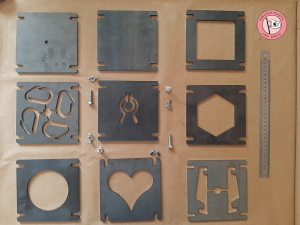

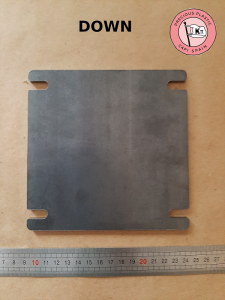

- Down Plate--> 6 mm thick, 150 mm x 150 mm. Lower part of the mold. Standard for all models. It is the base of the set.

- Top Plate --> 6 mm thick, 150 mm x 150 mm, top of mold. Standard for all molds. It is the upper part and where the molten plastic enters the mould (Diameter 8mm).

- Intermediate Plates --> 150 mm x 150 mm, is the part that is inserted between the top and down plate, with the desired shape to be molded. Several possibilities to choose from.

Moulds Included

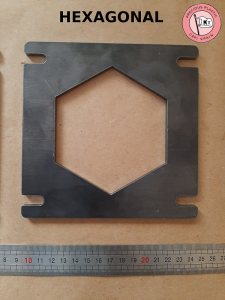

- Hexagon 55 mm side, Thickness 6 mm. Hexagonal Moulds.

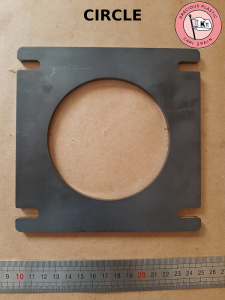

- Circle 100 mm diameter,Thickness 6 mm. Circle Moulds.

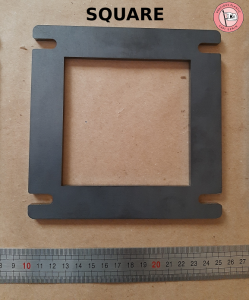

- Square 100 mm side, Thickness 6 mm.. Square Moulds.

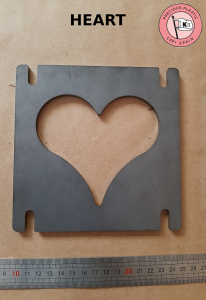

- Heart 112 mm x 100mm side ( Aprox.), Thickness 6 mm. Heart Moulds.

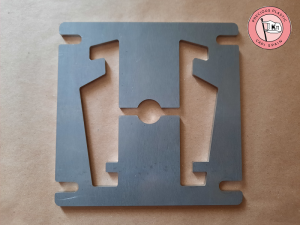

- Holder, Thickness 4 mm.. Holder Moulds.

- Pinza Piranna 80 mm x 50 mm aprox. Thickness 6 mm.

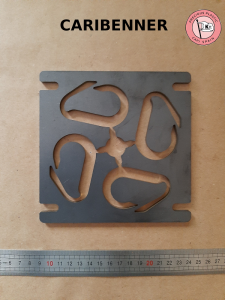

- Caribener 70 mm x 45 mm, Thickness 6 mm.

Stainless Steel A2 (AISI 304) bolts and nuts system for quick opening and closing, included.

Special design of the slotted screw holes for faster assembly/disassembly

Moulds NOT recommended for extruder use.

We recommend using one or more support points under the down plate to extend the life of the mould.

MEASUREMENTS

The Mediterranean Sea Series has been designed to offer versatility and compatibility between moulds, facilitating its use in diverse recycling projects.

Each of the molds in this series is part of a modular system, which allows interchangeable plates such as the top and bottom plates, while maintaining a common structure: SAVE COSTS.

Plastic Inlet

You may choose between;

Standard inlet. Diameter 8 mm

Conic Drill, we made a conic drill in the Top Plate, so the injector tip is adjusted to the inlet hole. It is our recommended system. Simplicity and speed in molding and demolding operations.

AMOUNT OF PLASTIC

In the following table, you will find an estimate of the amount of plastic required (in grams) to fill each of our molds, based on the density of the material used.

🔹 Example: If you are working with PP (polypropylene), its density may range between 0.90 g/cm³ and 0.91 g/cm³, which will directly affect the total amount required.

🔹 The figures shown are approximate values, intended to serve as a guide for efficient planning.

Attention:

Estimates do not include the plastic volume of the nozzle.

PVC has not been considered, as its handling and melting pose health and environmental hazards.

REGULAR STEEL OPTION AVAILABLE

Precious Plastic Capi Spain offers a version of its Mediterranean Sea moulds made from high-quality regular steel.

PLASTIC INLET (This option is offered only in regular steel.)

Usted podrá elegir entre;

- Standard inlet. Diameter 8 mm

- Conic Drill, we made a conic drill in the Top Plate, so the injector tip is adjusted to the inlet hole. It is our recommended system. Simplicity and speed in molding and demolding operations.

Threading system, we add a piece to be able to thread in the injector. We do not recommend it due to the problems of demolding when the plastic solidifies inside the threaded part. Our system allows to disassemble this piece for cleaning and later assembly.–> Nozzle male / Female.

TIPS

Plastic Inlet

Precious Plastic Capi Spain, recommends the Conic Drill plastic inlet option.

According to feedback from our clients and friends, using threaded inlets requires more time and effort. The plastic that remains in the threads cools down and solidifies, making it very difficult to remove before the next molding operation.

Support Points

Precious Plastic Capi Spain recommends the use of several support points under the Down Plate.

It will extend the life of your moulds. The force exerted on the Down Plate by the pressure of the plastic will be distributed among the support points.